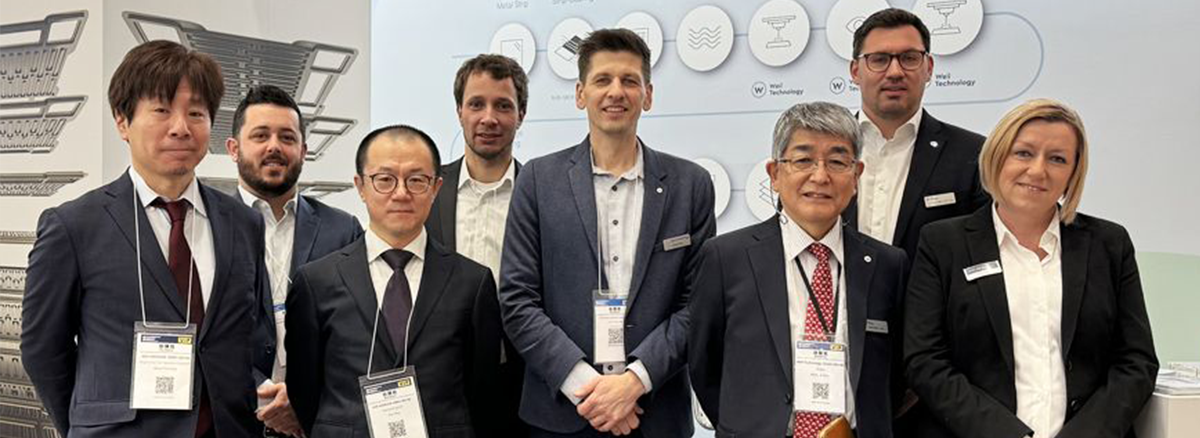

GERMAN FUEL CELL COOPERATION

YOUR PARTNERS FOR MANUFACTURING EQUIPMENT

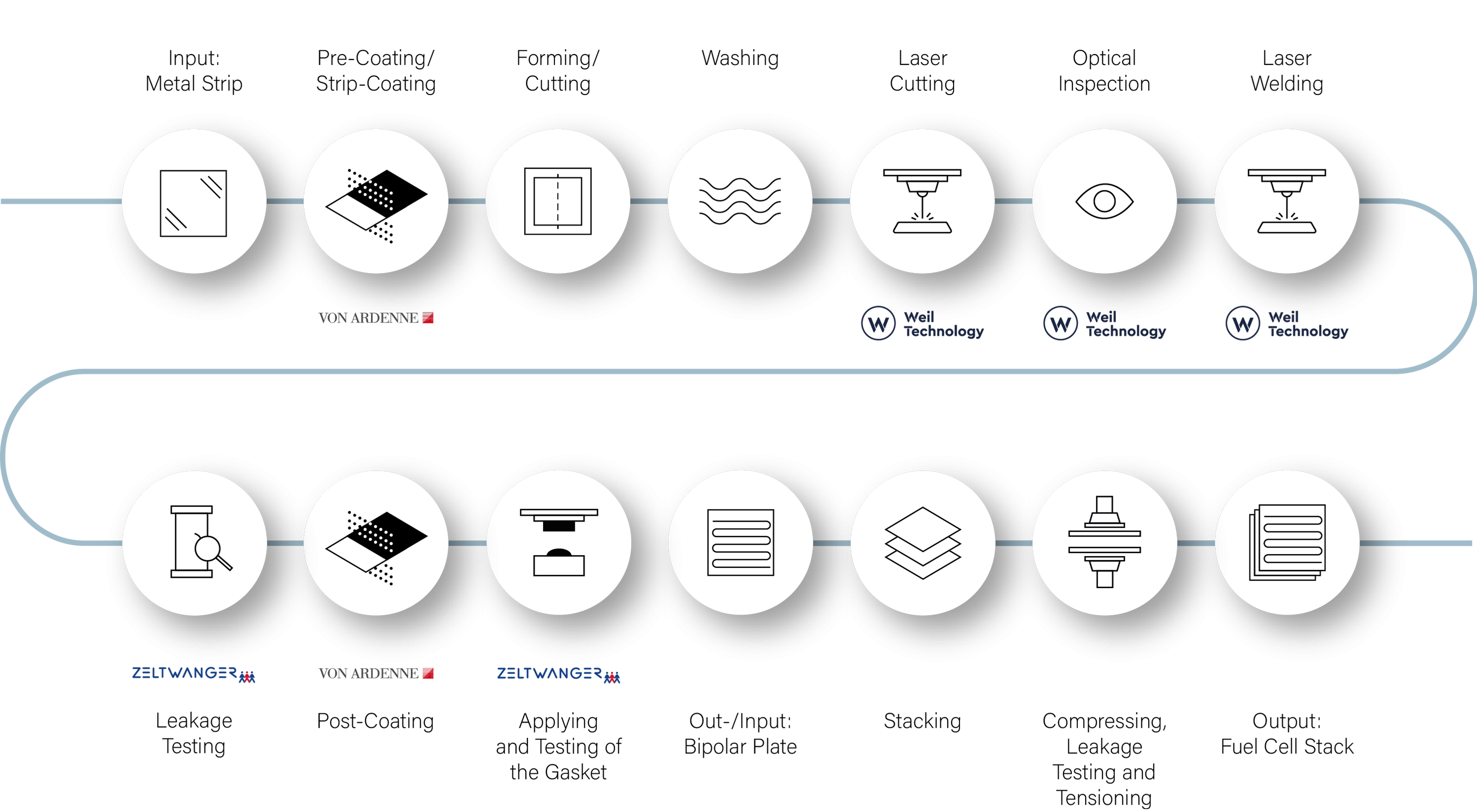

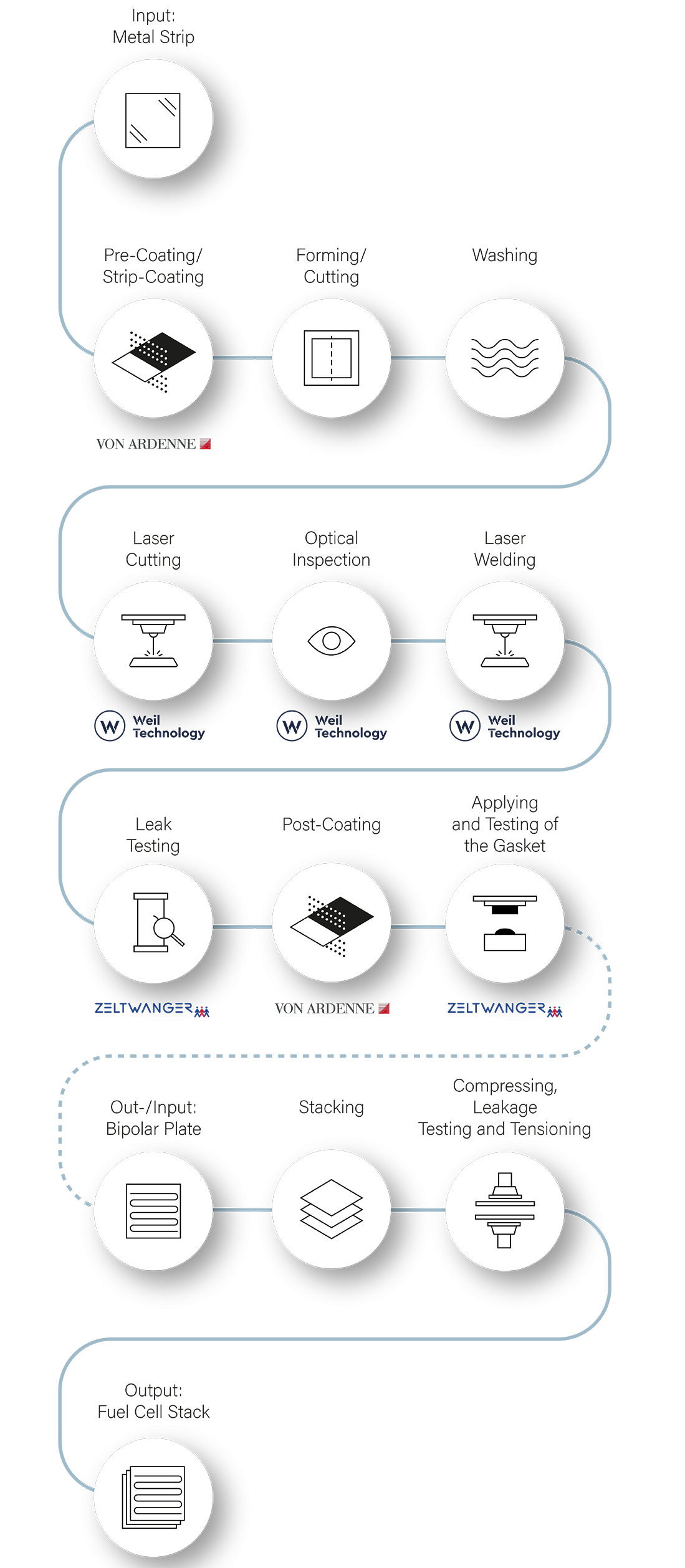

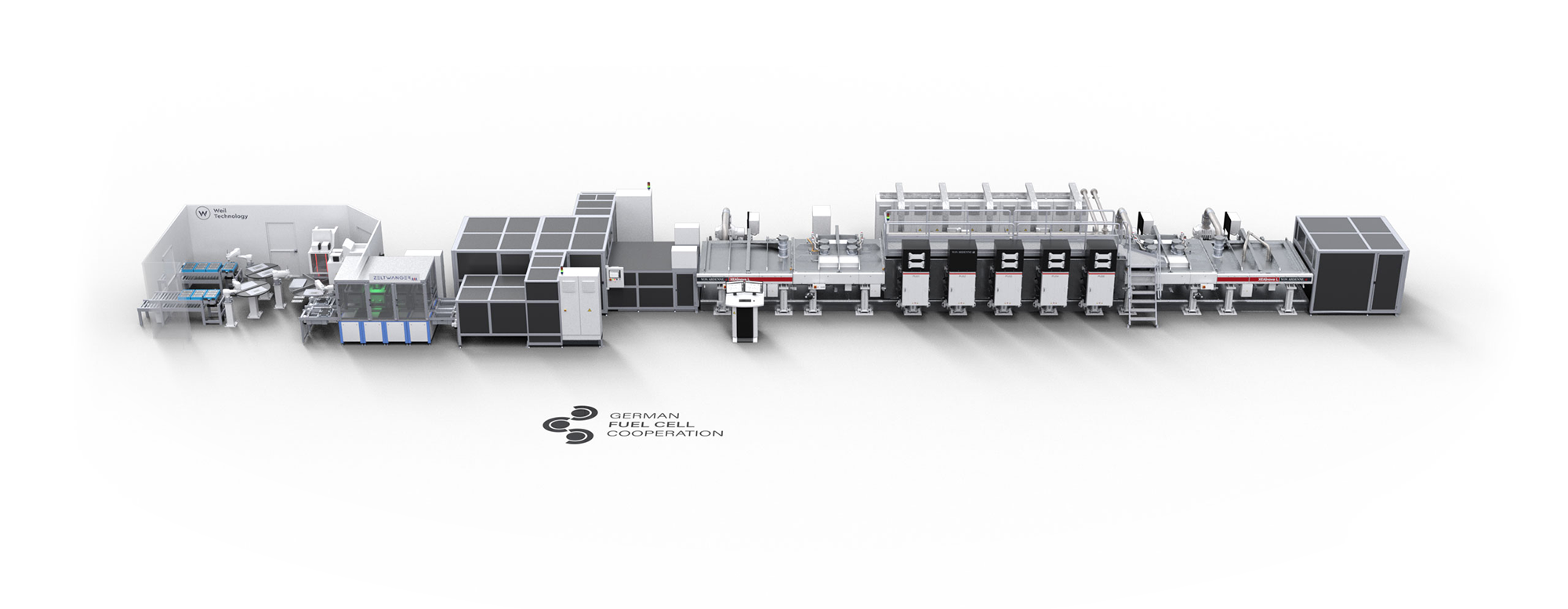

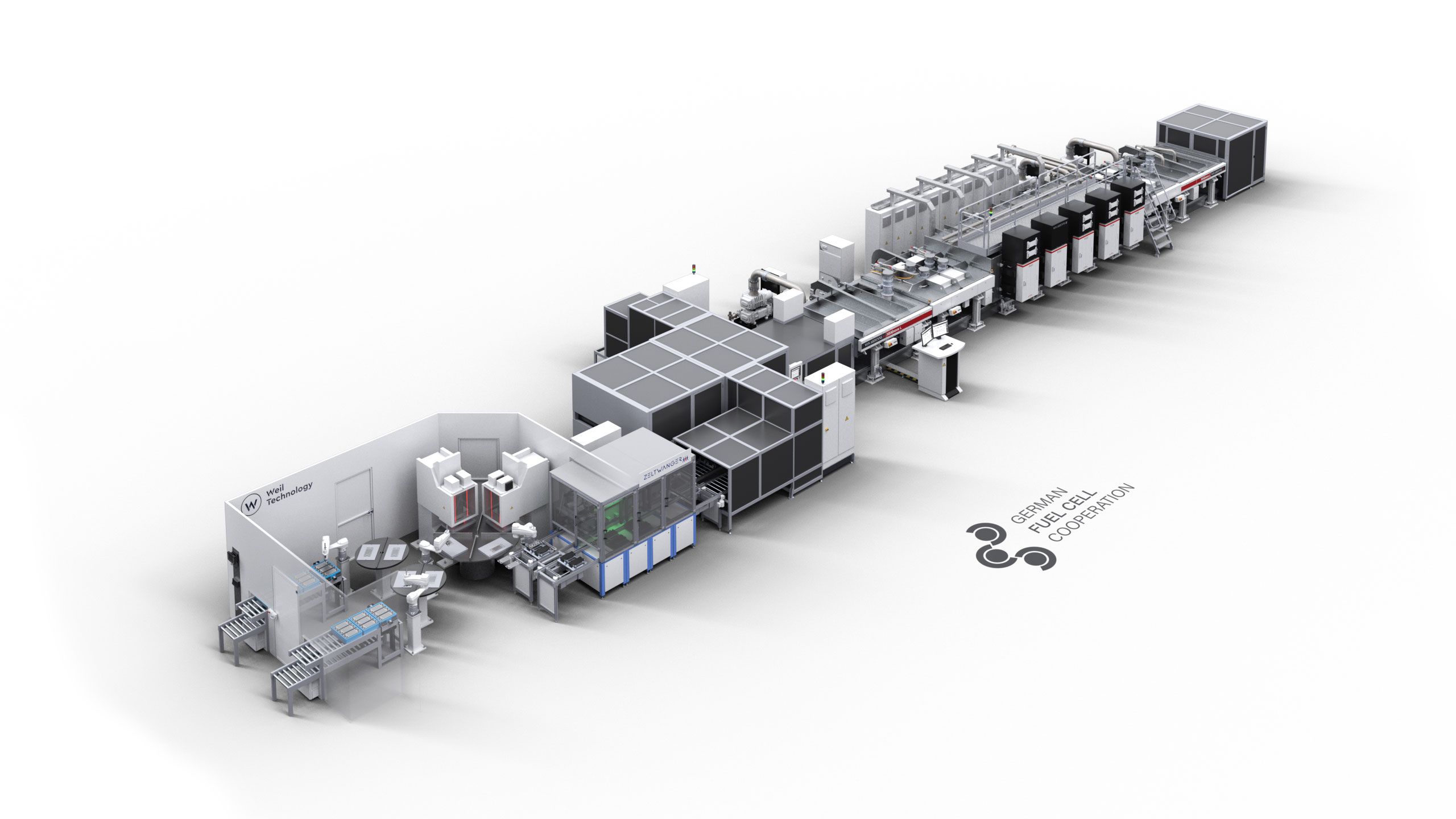

from metal strip to fuel cell or electrolyzer stack

How do you efficiently produce the fuel cell or electrolyzer of the future?

VON ARDENNE, Weil Technology and ZELTWANGER have asked themselves this question together. You can benefit from the expertise of all three companies at every step in the process chain and get your production ready for the fuel cell or electrolyzer of the future.

Your advantages at a glance

High process reliability with bundled know-how for every production step

Comprehensive traceability via the higher-level master controller

High-volume systems for series production from metal strip to BPP

Flexible and scalable plant technology adapted to the requirement

The manufacturing process of fuel cells

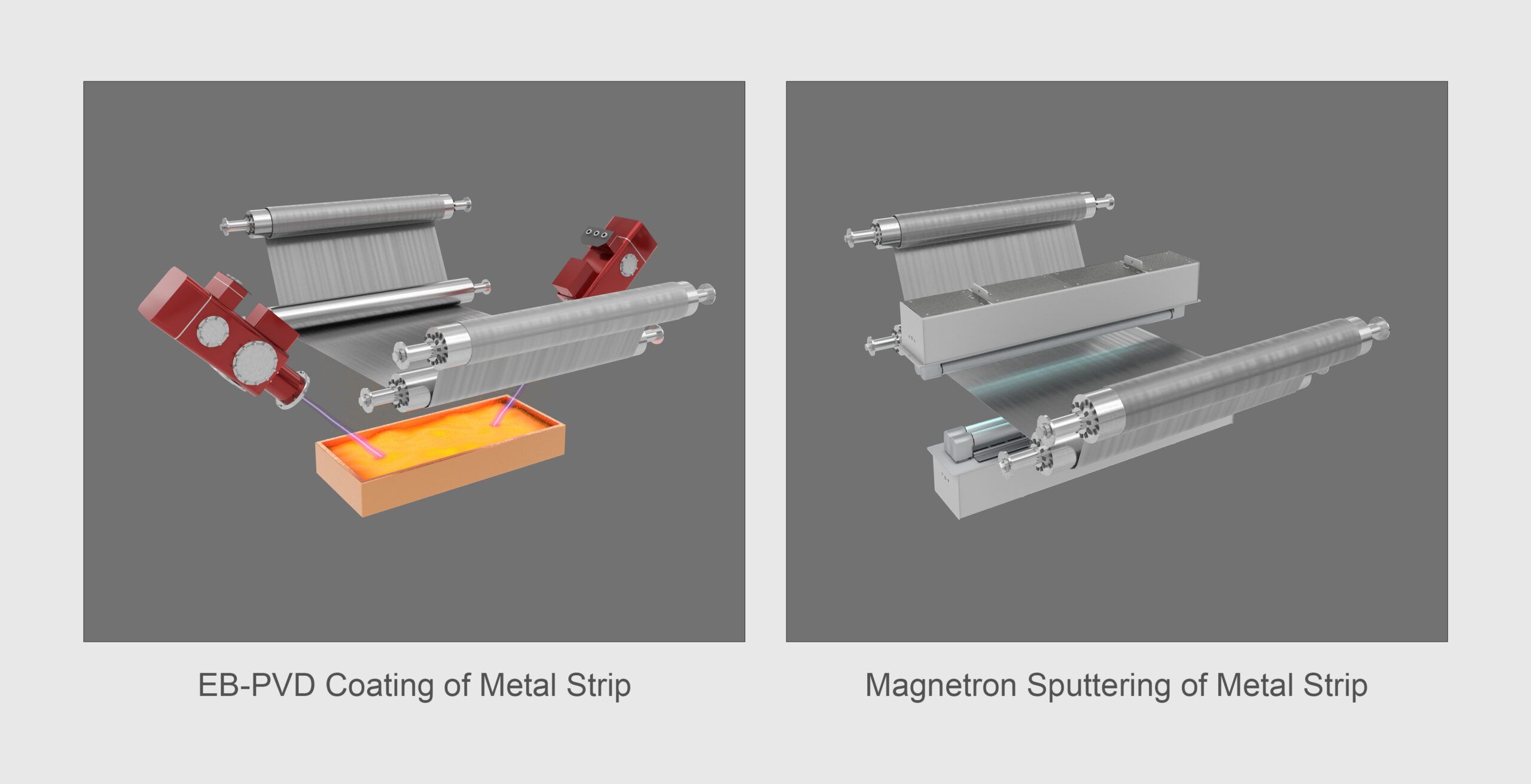

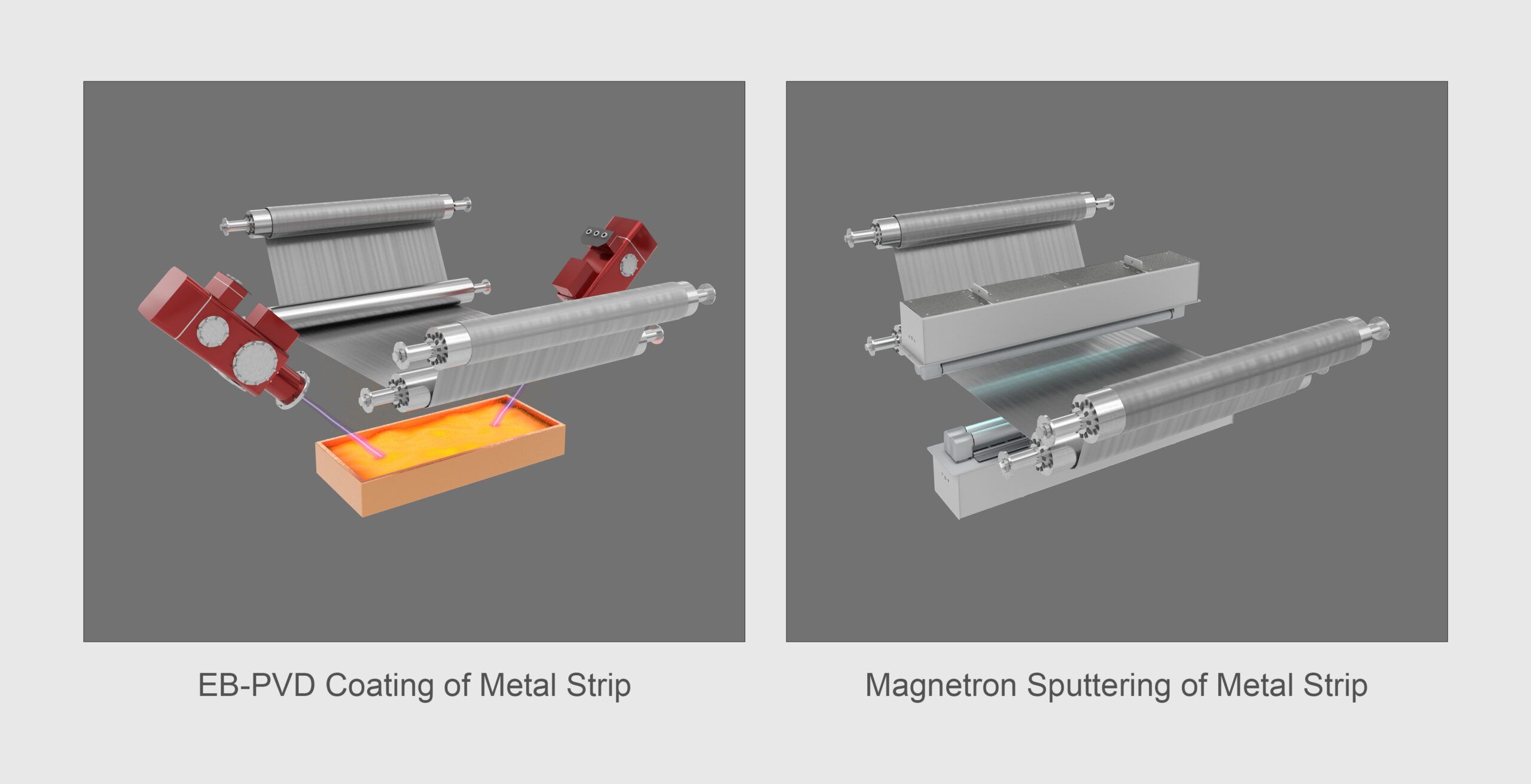

Vacuum based coating of metal strip substrates (Pre-Coating) for bipolar plates

Process

- Vacuum Coating of metal strip substrate

- Process component options:

- Plasma Pretreatment (surface activation / cleaning)

- PVD-Coating by magnetron sputtering or electron beam evaporation

- Heating / Cooling

Benefits from coating metal substrates

- Mechanical and chemical stability

- Low interfacial contact resistance

- Low coating costs

- Electrical and thermal conductivity

- Corrosion resistance

- Long lifetime

Learn more or contact us directly

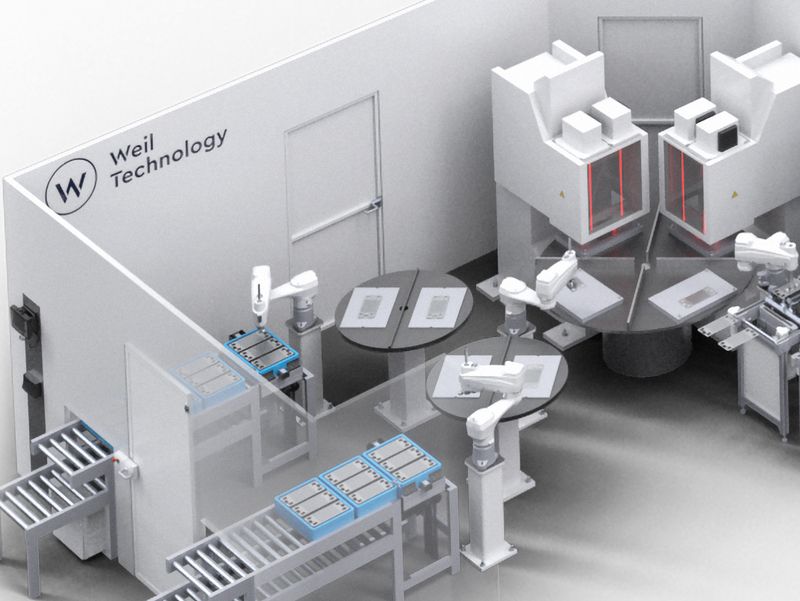

Laser cutting

By using laser technology, you avoid the use of high-maintenance tools and react flexibly to contour changes.

System advantages

- Cutting speed up to 50 m/min

- Highest dynamics through linear direct drives

- Contour accuracy up to +/- 0,02 mm

- For standard plate format up to 500 x 165 mm, a doubled mold is possible

- Highest cutting quality due to real-time controlled power regulation

- Automated loading and unloading from KLT or belt system

Learn more or contact us directly

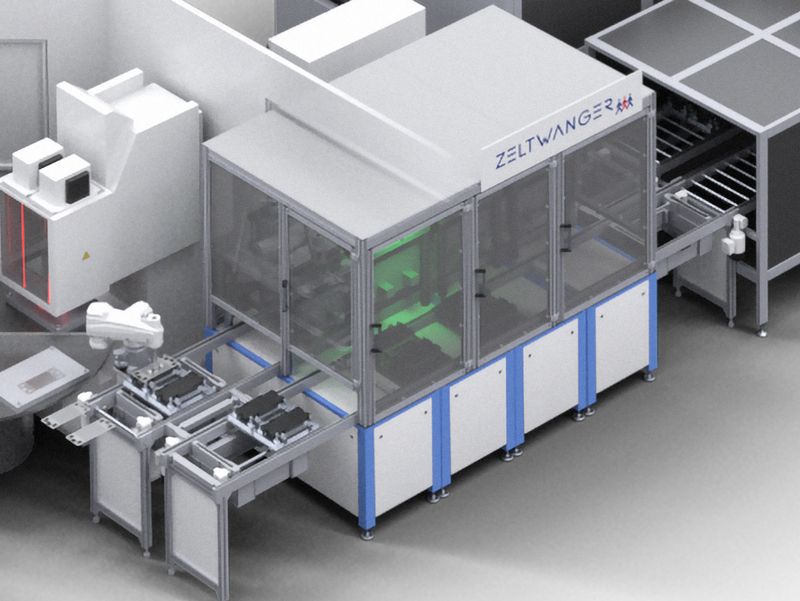

Optical inspection

- Optical inspection of the coating for homogeneity/defects

- Checking the orientation of the plate before loading

Learn more or contact us directly

Laser welding

System advantages

- Patent-pending welding modules with large working area of 500 x 350 mm

- Dual field scanner technology for an absolute welding speed of 1000 mm/s for maximum output

- Reduced thermal distortion due to symmetrical heat input with Butterfly Weld

- Double panel loading is possible for panel sizes up to 500 x 165 mm

- Low space requirement

Learn more or contact us directly

Leak testing

- Use of all common test methods possible (pressure drop, detection gas test with helium)

- High flexibility due to easily exchangeable sealing devices as well as the use of the modular ZELWANGER measuring inserts ZEDcore

- Scalable test systems incl. semi- to fully-automatic loading and unloading process

- Achieving the shortest possible test times through the use of specially developed measuring circuits and test fixtures

- Preliminary tests as well as measuring equipment capability tests in our own application laboratory or at the customer’s site

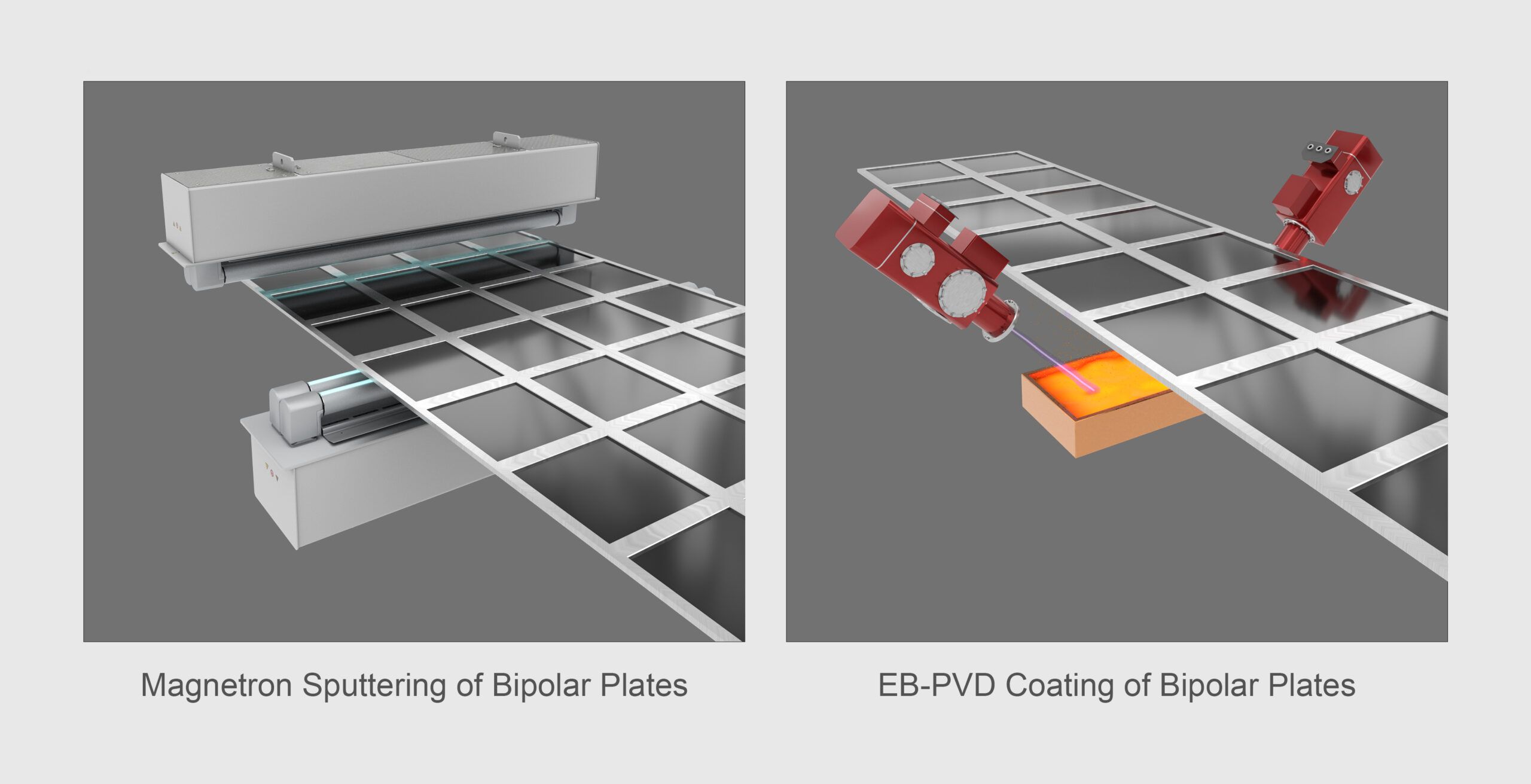

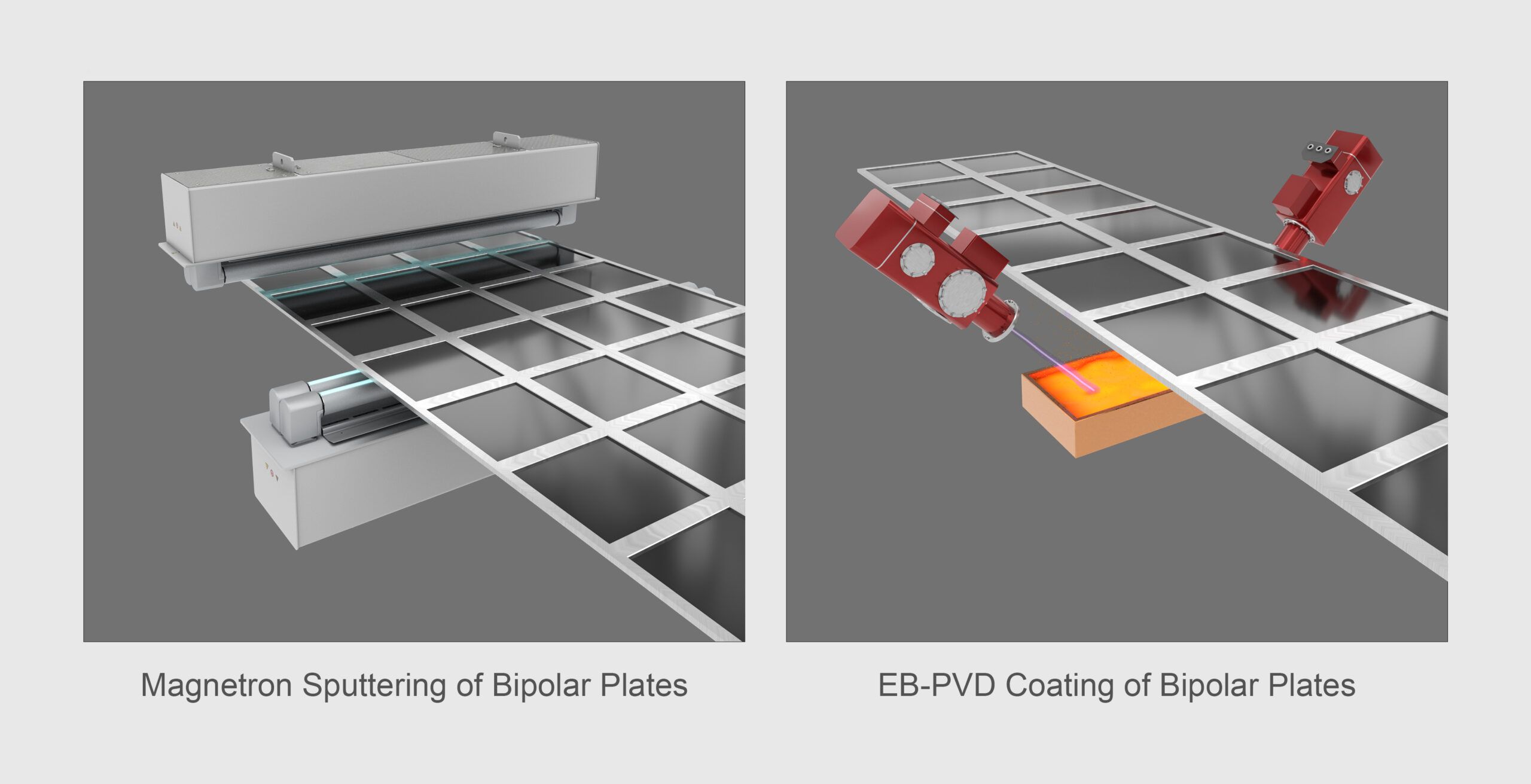

Vacuum based coating of metal bipolar plate substrates (Post-Coating)

Process

- V- Vacuum Coating of metal bipolar plates

- Process component options:

- Plasma Pretreatment (surface activation / cleaning)

- PVD-Coating by magnetron sputtering or electron beam evaporation

- Heating / Cooling

Benefits from coating metal substrates

- Mechanical and chemical stability

- Low interfacial contact resistance

- Low coating costs

- Electrical and thermal conductivity

- Corrosion resistance

- Long lifetime

Learn more or contact us directly

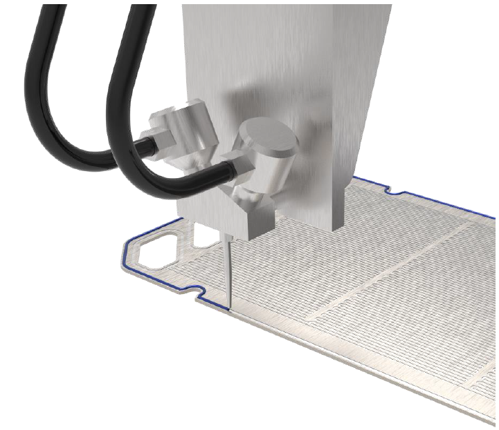

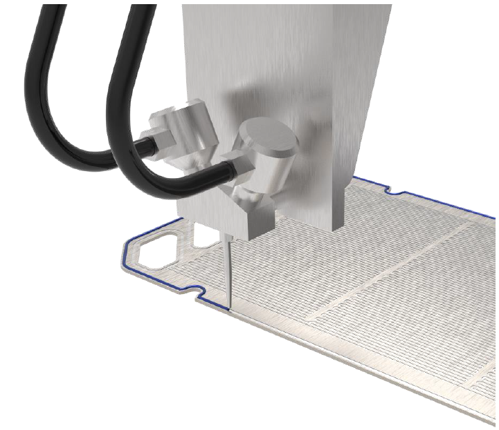

Application and testing of the seal

Automated application of sealing compound

- 1K or 2K sealants

Process monitoring

- Volume flow monitoring

- Visual inspection of the sealing bead „on the fly“

Hardening

Advantages

- Automated process for high productivity

- Highly accurate dosing of the sealing

material possible - Optical inspection of the sealing lip after

application optional

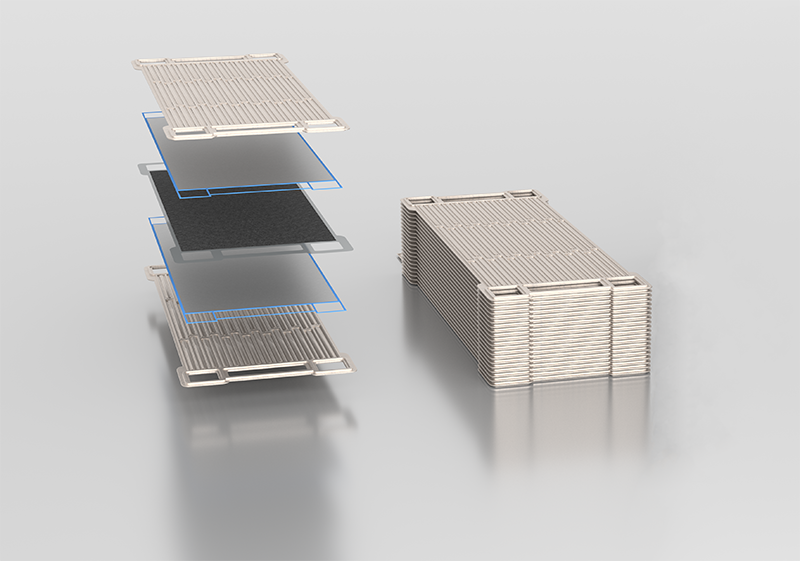

Bipolar plate

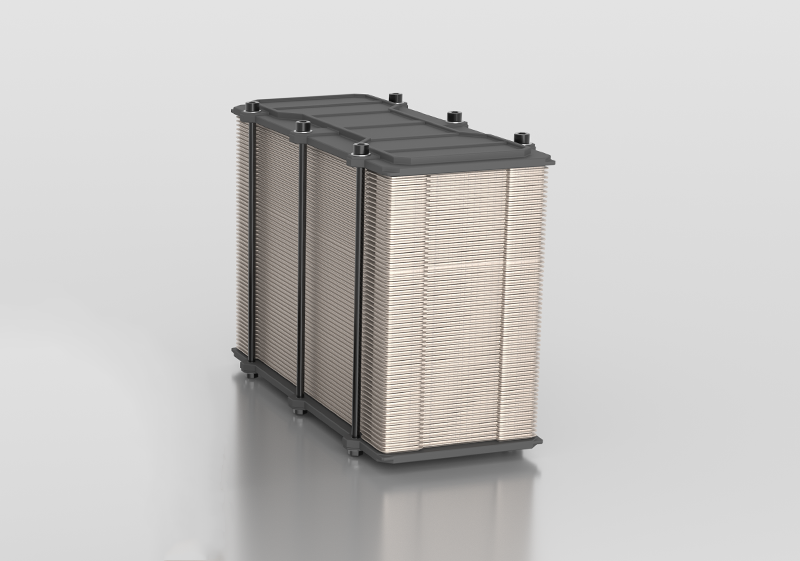

Compression, leak testing and clamping

Pressing of the stacked fuel cell stack

- Force-displacement monitored pressing of the stack by means of servo presses

- Free parameterization of the force and/or displacement over time

Leak testing of the fuel cell stack

- Fully automatic testing of external and internal leakages of the individual test chambers to each other (anode, cathode, cooling)

- Allocation of the leakage channel possible using highly accurate flow measuring circuits

Clamping of the fuel cell stack

- Manual or automatic clamping of the stack possible by means of metal straps or threaded rods

Fuel cell stack

Process

- Vacuum Coating of metal strip substrate

- Process component options:

- Plasma Pretreatment (surface activation / cleaning)

- PVD-Coating by magnetron sputtering or electron beam evaporation

- Heating / Cooling

Benefits from coating metal substrates

- Mechanical and chemical stability

- Low interfacial contact resistance

- Low coating costs

- Electrical and thermal conductivity

- Corrosion resistance

- Long lifetime

Learn more or contact us directly

By using laser technology, you avoid the use of high-maintenance tools and react flexibly to contour changes.

System advantages

- Cutting speed up to 50 m/min

- Highest dynamics through linear direct drives

- Contour accuracy up to +/- 0,02 mm

- For standard plate format up to 500 x 165 mm, a doubled mold is possible

- Highest cutting quality due to real-time controlled power regulation

- Automated loading and unloading from KLT or belt system

Learn more or contact us directly

- Optical inspection of the coating for homogeneity/defects

- Checking the orientation of the plate before loading

Learn more or contact us directly

System advantages

- Patent-pending welding modules with large working area of 500 x 350 mm

- Dual field scanner technology for an absolute welding speed of 1000 mm/s for maximum output

- Reduced thermal distortion due to symmetrical heat input with Butterfly Weld

- Double panel loading is possible for panel sizes up to 500 x 165 mm

- Low space requirement

Learn more or contact us directly

- Use of all common test methods possible (pressure drop, detection gas test with helium)

- High flexibility due to easily exchangeable sealing devices as well as the use of the modular ZELWANGER measuring inserts ZEDcore

- Scalable test systems incl. semi- to fully-automatic loading and unloading process

- Achieving the shortest possible test times through the use of specially developed measuring circuits and test fixtures

- Preliminary tests as well as measuring equipment capability tests in our own application laboratory or at the customer’s site

Process

- V- Vacuum Coating of metal bipolar plates

- Process component options:

- Plasma Pretreatment (surface activation / cleaning)

- PVD-Coating by magnetron sputtering or electron beam evaporation

- Heating / Cooling

Benefits from coating metal substrates

- Mechanical and chemical stability

- Low interfacial contact resistance

- Low coating costs

- Electrical and thermal conductivity

- Corrosion resistance

- Long lifetime

Learn more or contact us directly

Automated application of sealing compound

- 1K or 2K sealants

Process monitoring

- Volume flow monitoring

- Visual inspection of the sealing bead „on the fly“

Hardening

Advantages

- Automated process for high productivity

- Highly accurate dosing of the sealing

material possible - Optical inspection of the sealing lip after

application optional

Pressing of the stacked fuel cell stack

- Force-displacement monitored pressing of the stack by means of servo presses

- Free parameterization of the force and/or displacement over time

Leak testing of the fuel cell stack

- Fully automatic testing of external and internal leakages of the individual test chambers to each other (anode, cathode, cooling)

- Allocation of the leakage channel possible using highly accurate flow measuring circuits

Clamping of the fuel cell stack

- Manual or automatic clamping of the stack possible by means of metal straps or threaded rods

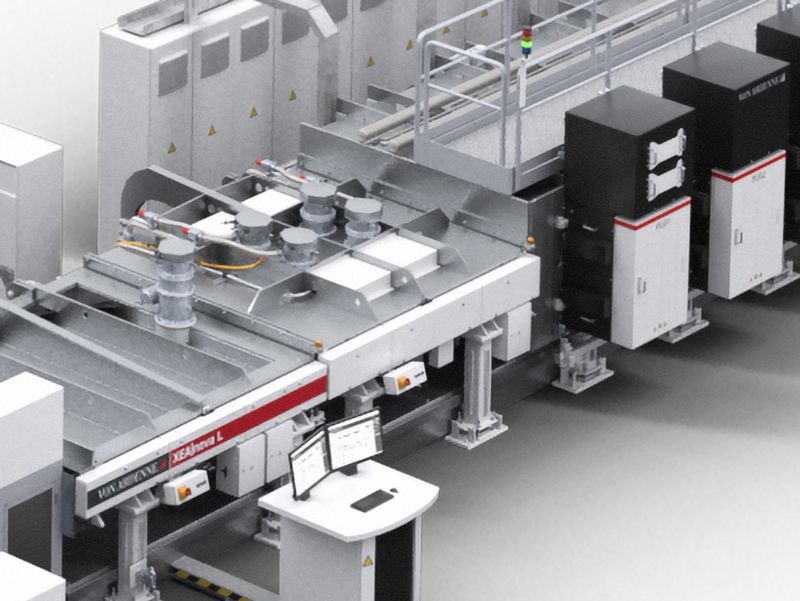

Fully automated and chained production line

Laser welding

LWC-RT4

Leak testing

ZED BPP 4-2

PVD coating

XEA | nova L8

GERMAN FUEL CELL COOPERATION

By loading this video, you accept the YouTube Privacy Policy.

Find out more

GFC Production line

By loading this video, you accept the YouTube Privacy Policy.

Find out more

Companies

VON ARDENNE GmbH

Founding year: 1991

Employees: 1000 (worldwide)

Headquarter: Dresden

Competence fuel cell:

- Development and manufacturing of equipment for functional coatings, e.g. on metal bipolar plates

- R&D, pilot- and high-volume production equipment for embossed bipolar plates (post-coating) and strip material (pre-coating)

- Joint technology development and sampling

NEWS

VISIT US AT THESE TRADE FAIRS AND EVENTS:

Euroblech

International Sheet Metal Working Technology Exhibition

October 22 – 25, 2024 | Hannover, Germany

Exhibitor: Weil Technology

FC³ Chemnitz

Conference on current fuel cell research in conjunction with efficient manufacturing processes

November 12 – 13, 2024 | Chemnitz, Germany

Exhibitor: VON ARDENNE

Contact

Susann Puppe

Sales & Business Development Manager

Hydrogen & Fuel Cell

VON ARDENNE GmbH

Tel.: +49 351 2637 9748

Puppe.Susann@vonardenne.com

Thomas Frey

Manager of Development

Laser Cutting Technology and E-Mobility

Weil Technology GmbH

Tel.: +49 7631 1809 0

t.frey@weil-technology.com

Jochen Kober

Industry Manager E-Mobility

ZELTWANGER Gruppe

Tel.: +49 7072 92897 536

J.Kober@zeltwanger.de

Contact us now

Thank you for your interest in the German Fuel Cell Cooperation.